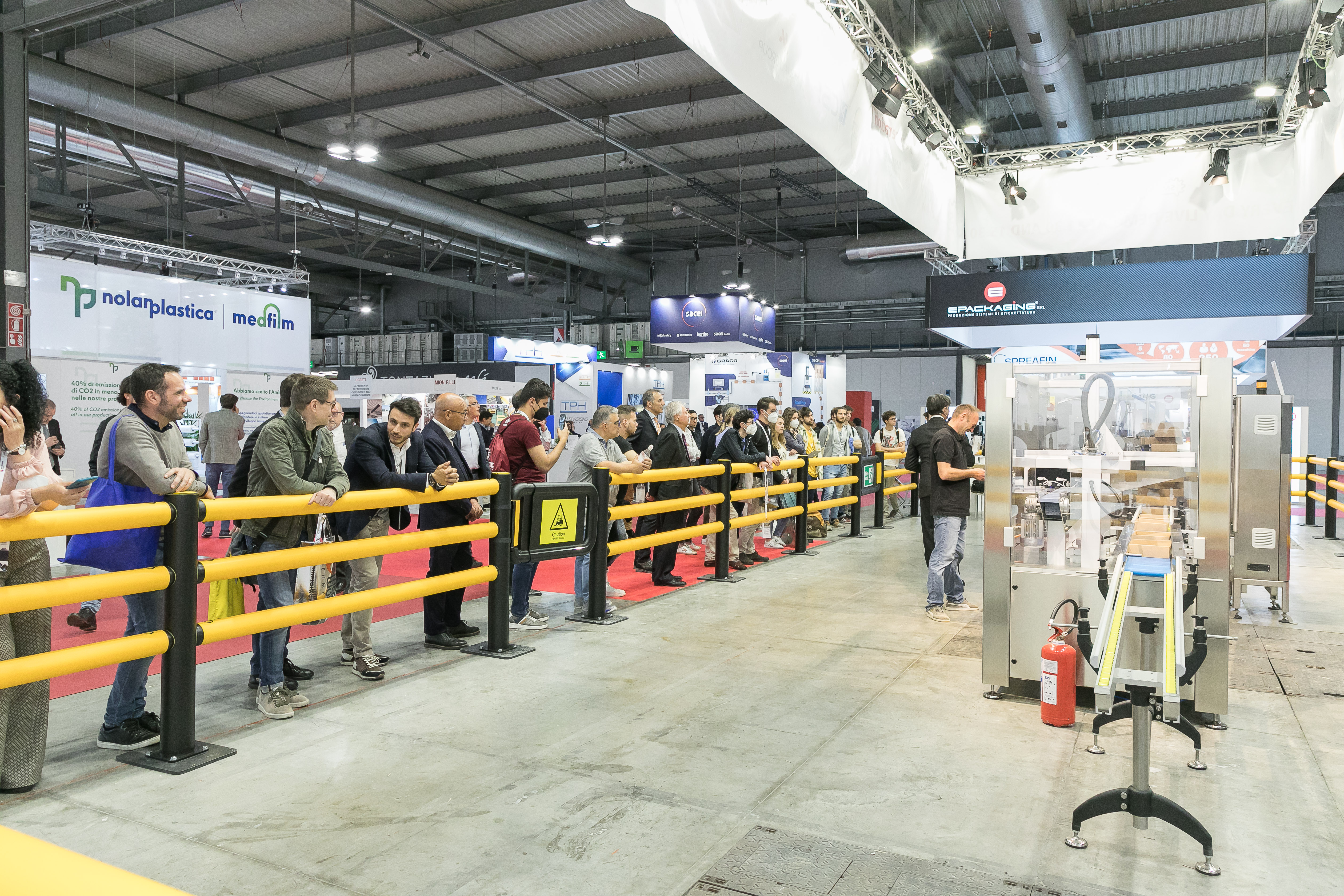

Every day at 11:30 a.m. and 3:30 p.m. production runs in Hall 4 - C62 / B77

Smart Factory - Hall 4, stand

Smart Factory by Ipack Ima is an innovative, smart and sustainable production line created thanks to the cooperation of IPACK-IMA exhibitors, which will offer the entire international audience production runs where they can follow the production and packaging of single-portion hummus live.

The exhibitors who will collaborate in the Smart Factory will build a complete production line, starting from the process of transformation and processing of the vegetable product, making the semi-processed product, then packaging it in single-serving trays, and finishing the steps with a labelling and end-of-line solution.

They will each take care of one step in the preparation process with the best of their technologies and materials, to demonstrate the cooperation and integration, including digital integration, of their systems.

Particular attention will be paid to the packaging materials used, with a strong emphasis on sustainability, combined with a focus on product quality, preservation and traceability. Innovation, sustainability, automation, technical expertise and co-generation: these are the keywords of the Smart Factory by Ipack Ima

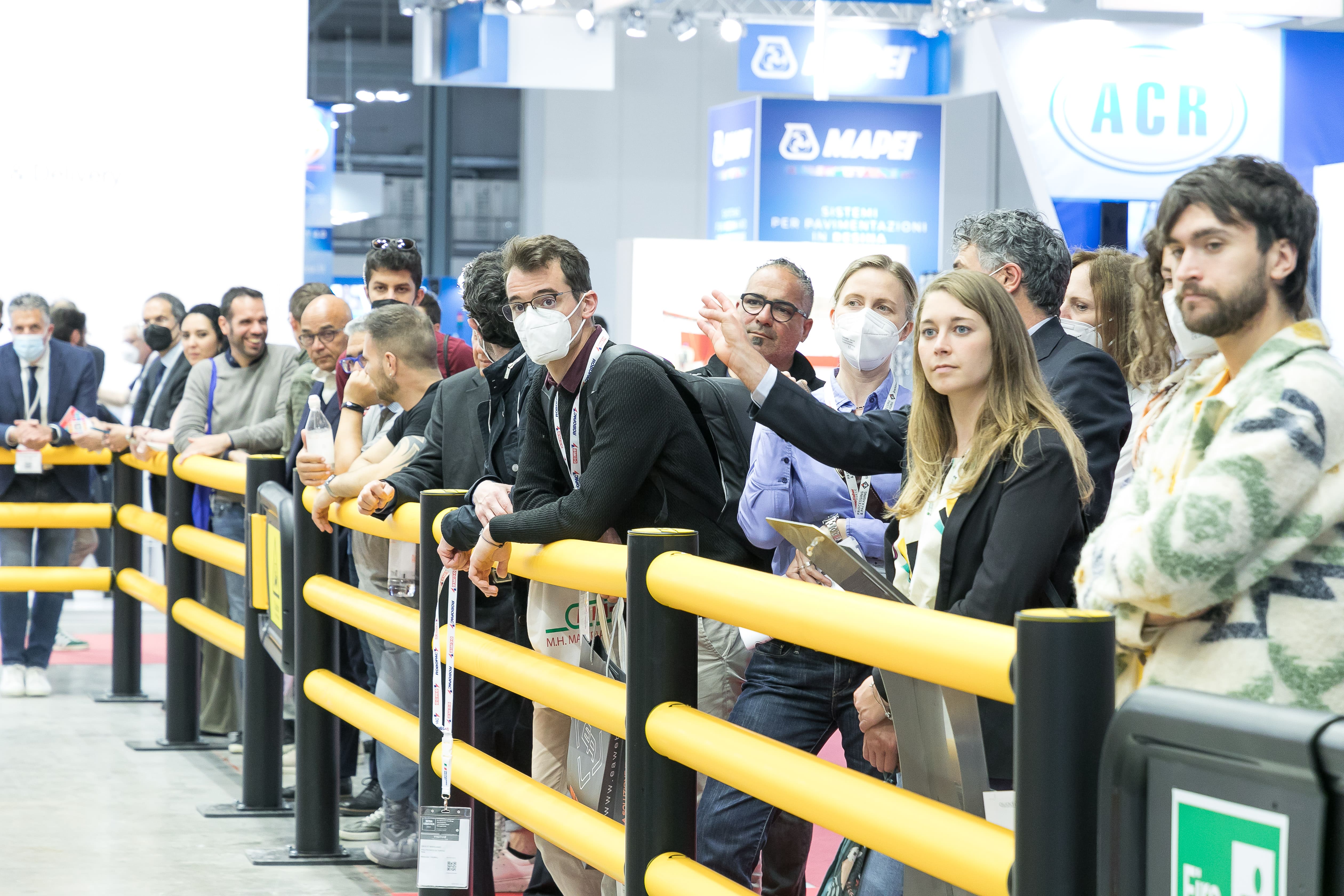

A-SAFE

A-SAFE is the world's leading manufacturer of safety barriers and impact protection made of Memaplex polymer, a flexible polyolefin blend that absorbs and dissipates shock. A-SAFE products can drastically reduce maintenance costs and increase the level of security within companies and logistics warehouses.

READ MOREFor the Smart Factory, it will create protective barriers to enclose the entire perimeter. A-safe products will protect machinery, eliminate risks to visitors and ensure the protection of an efficient hummus production line.

READ MORE

ANTARES VISION

Antares Vision Group offers an ecosystem of technologies to ensure the quality and traceability of products along the supply chain (from raw materials, through production, distribution to the consumer), with integrated data, production and supply chain management, including through the application of artificial intelligence and the use of blockchain.

READ MOREIn the Smart Factory the finished pack of hummus will be ready to be screened by FT System and its Combi X system, which will inspect each unit coming out of the FS2500 to ensure that it is of the required weight and that there are no bodies of a different consistency to our product.

READ MORE

CSF

CSF is one of the leading companies in Italy and Europe for the production of pumps designed mainly for the food and beverage, dairy, chemical and pharmaceutical industries. The company offers a range of centrifugal, self-priming, eccentric screw, twin screw, sinusoidal rotor and pneumatic pumps.

READ MOREIn the Smart Factory, the main objective of CSF Inox is to offer a higher standard of quality. CSF pumps have to be distinguished by their stability and reliability as well as providing excellent performance for the production of our hummus.

READ MORE

DI MAURO GROUP

125 years of history and a strong vision for the future - for more than 100 years the DI Mauro Group has been a benchmark in the printing industry. The family, the management and 240 people work to meet the daily development and the challenges of an ever-changing market.

READ MOREPeelable paper-dominated cover top, suitable for food contact, disposable in the paper stream. In the Smart Factory, the Fill Seal 2500 will dose the Hummus into unstacked paper containers and seal it with a film made of easily recyclable paper material, supplied and produced by Di Mauro Group.

READ MORE

ILPRA

Ilpra will lead the demonstration packaging line. In the Smart Factory, once the optimal result of our hummus is achieved, the FS2500 rotary machine will channel and take over the product. The machine will be fully automatic and electronic. During the sealing phase, ILPRA's technology will allow a protective gas mixture to be injected into the container to prolong the shelf life of the product.

READ MOREOnce the control phase has been completed, our hummus pack is once again taken over by ILPRA SpA with the help of the RC end-of-line system, an automatic tray packer that picks up the heat-sealed cups from the conveyor belt and gently places them in pre-formed boxes ready for palletising.

READ MORE

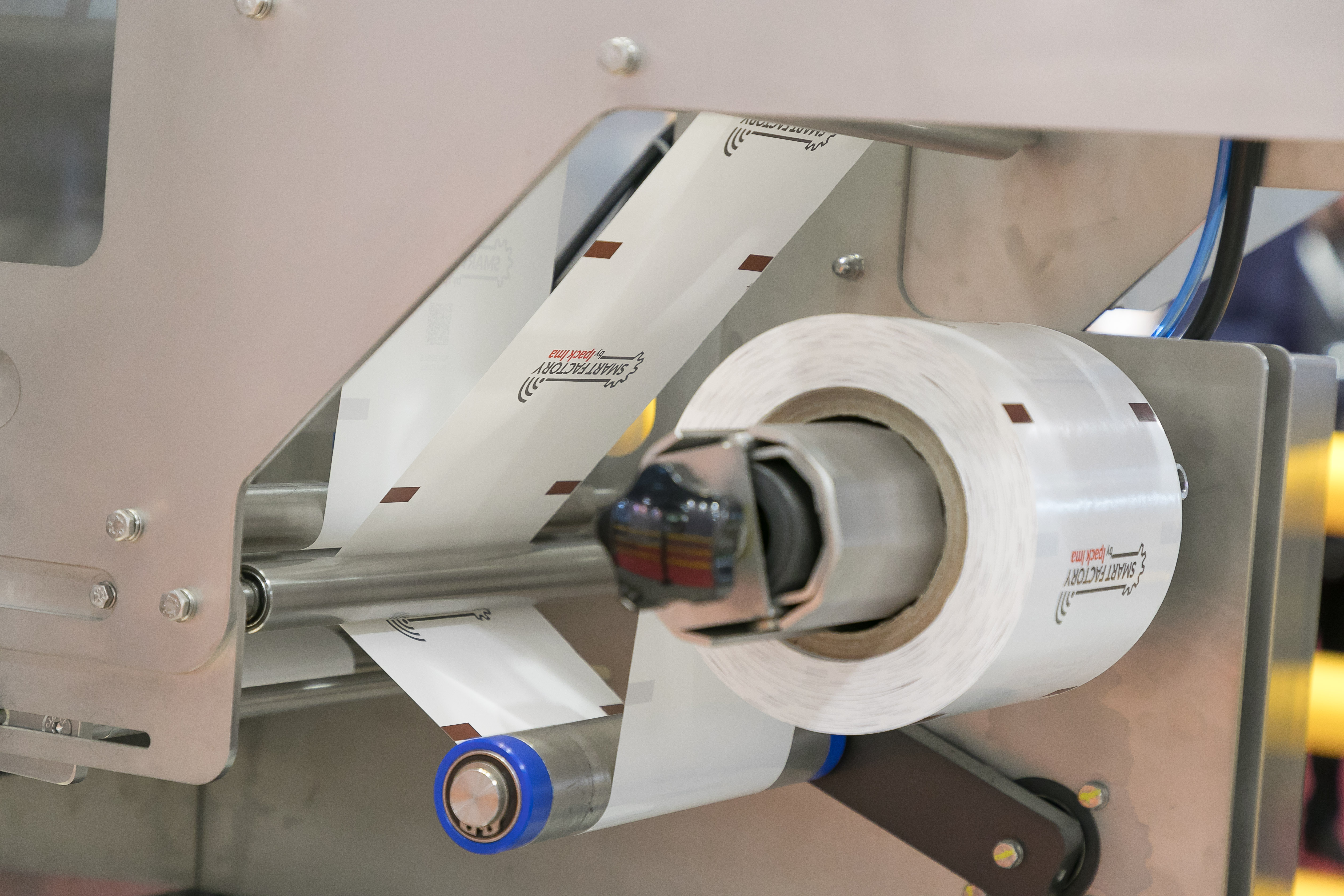

MARKEM IMAJE

Markem-Imaje, a global brand of Dover Corporation, connects products with consumers and helps protect brands through intelligent coding and traceability solutions. Markem calls itself the intelligence beyond the mark. More than 50,000 customers worldwide rely on Markem to optimise efficiency in their supply chains and achieve better quality and sustainability.

READ MOREFor the Smart Factory Markem Imaje will be involved in the final production phase of our hummus. The entire fully automatic packaging line will end with the labelling of the single-serving hummus packs.

READ MORE

SIEMENS

Siemens' portfolio of digital solutions integrates seamlessly with automation applications for the packaging industry, reducing time-to-market and increasing system availability. The technological support of TIA Portal offers machine builders an efficient design environment with less complexity.

READ MOREOnce the optimal result of our product has been achieved in the Smart Factory, the hummus will be channelled into the hopper and taken over by a fully automatic rotary machine, equipped with electronics, panel and PLC signed Siemens, a brand guaranteeing reliability, which allows easy setting of the parameters.

READ MORE

ROBOQBO

More than 40 years of research and innovation have given Roboqbo first-class know-how in raw material processing. Roboqbo produces Qbo - Universal Processing System, an extremely versatile, innovative and high-tech working system, capable of producing any type of preparation in a very short time and in a single process.

READ MORERoboqbo participates in the Smart Factory at the very first stage of the process. Everything will start in RoboQb's QBO 120 unit, a system capable of cooking, cooling, concentrating, vacuum refining any product and which will then prepare the Hummus according to the optimal production requirements.

READ MORE